An innovative special material option for pipe clamps

The requirements for pipe clamps in potentially explosive atmospheres (so-called EX areas) are constantly increasing. In order to meet these specific market requirements, we at STAUFF have further developed our tried and tested standard components. The result is a new special material option called PA-EX, which is manufactured for various tube diameters on customer request.

This addition to our range is an example of how we are adapting the performance of our clamp bodies to fulfil the highest safety standards - especially where electrical conductivity and explosion protection are crucial.

Properties and special features of the special material

The aim in developing the clamp was to create a safety solution that is not only robust and reliable, but also offers targeted electrical discharge capabilities to minimise potential hazards from electrostatic charges. The PA-EX clamp was subjected to the following tests and standards for qualification:

Dissipation resistance according to heat resistance test (DIN EN IEC 60079-0)

PA-EX was subjected to the heat resistance test, which is carried out in accordance with the international standard DIN EN IEC 60079-0. This test measures the leakage resistance of the clamps - a critical parameter for safe operation in potentially explosive atmospheres. The test result shows that PA-EX clamps have a leakage resistance of less than 1 Ω, which means that electrical potentials can be safely discharged

Surface resistance (IEC 61340-5-1)

Another important test concerns surface resistance. In accordance with IEC 61340-5-1, the ability of the material to form electrostatic discharges is assessed. A surface resistance of less than 10³ Ω was measured for PA-EX clamps. This measurement is essential to ensure that electrostatic charges cannot lead to sparking, which could become critical in potentially explosive environments.

Transferred charge (IEC60079-32-2 )

In addition, our new clamp has undergone electrostatic hazard testing for transferred charge, as conducted in conjunction with IEC 60079-32-2. These tests show that PA-EX clamps have no transferred charge capability. This means that the material does not store any electrostatic energy, which in an unfavourable case could lead to the ignition of potentially explosive media.

The role of the International Electrotechnical Commission (IEC)

The standards mentioned above were developed by the International Electrotechnical Commission (IEC) - a globally recognised organisation that creates standards in the field of electrical engineering, electronics and information technology. These international standards are essential to ensure the safety, compatibility and performance of electrical components. Compliance with these standards ensures that the clamps can also be used reliably in demanding and safety-critical applications. The results were independently determined and documented by TÜV.

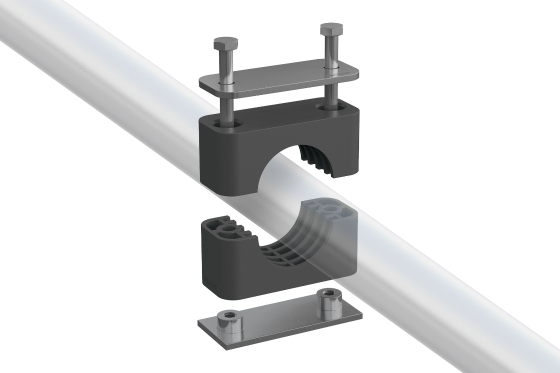

The determined results relate to clamp bodies with the design of the standard series in accordance with DIN 3015 (Part 1), which were installed with metal parts made of stainless steel AISI 316Ti (1.4571) - i.e. weld-on plate, screws and cover plate. This corresponds to STAUFF's installation recommendation. The results may vary considerably in some cases for different series and configurations.

The tube used for testing is also made of stainless steel AISI 316Ti (1.4571).

Advantages of PA-EX compared to other materials

PA-EX offers a number of advantages:

Safe operation in EX areas: Thanks to their defined electrical conductivity, PA-EX clamps help to dissipate electrostatic potentials and increase safety in potentially explosive environments.

Tested quality: The material properties have been independently documented by TÜV and comply with international IEC standards drawn up by the International Electrotechnical Commission.

Prevention of contact corrosion: PA-EX comes into play where metal or aluminium clamps reach their limits in certain applications. This is because direct contact between aluminium (clamps) and stainless steel (pipe) can lead to contact corrosion. This is prevented by the new special material.

Customised production: Manufactured on customer request and specially adapted to the requirements of the respective area of application, PA-EX fulfils individual requirements and thus offers greater flexibility.

Areas of application for PA-EX clamps

PA-EX clamps are primarily used in applications in which explicitly high safety requirements are placed on the electrical discharge. Typical areas of application are

Hydrogen systems

Tank farms in the chemical industry

Refineries

Petrol stations

Biogas plants

Underground mining

Industrial suction systems

Processing of bulk materials such as powder, granulate or cement

Before using our clamps, the suitability must always be checked by an EX expert using the data sheet information.

All Info at a Glance

Our PA-EX special material data sheet provides you with a clear and concise summary of all the information

Important notes on installation

To ensure reliable operation of PA-EX clamps, it is essential to follow the installation instructions exactly:

Unpainted individual parts: Before installation, ensure that all individual parts of the pipe clamp are unpainted, as paintwork can have a negative impact on electrical conductivity.

Pipe surface: The electrical conductivity of the clamp depends largely on the surface of the pipe used. Different pipe materials or surface coatings can lead to different conductivities.

Standardised system: Electrical conductivity must always be considered in the overall context of the system. Even if PA-EX contributes to the discharge, external earthing cannot be completely dispensed with. The fully installed and earthed system should therefore be checked regularly by suitably qualified personnel.

Installation and shoring instructions: The installation and shoring instructions and pipe retention forces apply as listed in the technical appendix of the current STAUFF clamp catalogue.

PA-EX as part of a safe system

PA-EX is a component that contributes to conductivity as part of a comprehensive safety concept. Nevertheless, electrical conductivity must always be assessed in the context of the entire system. External earthing and additional measures for discharge capability are often essential in order to fulfil the strict safety requirements in EX areas. It is therefore recommended that the entire system is checked by a specialist to ensure compliance with the relevant national and application-specific standards.

FAQs

How can I order PA-EX?

Can PA-EX replace aluminium clamps?

Yes, PA-EX is an alternative to electrically conductive aluminium clamp bodies in some applications.

Which standards must be observed during use?

PA-EX has been tested in accordance with IEC 60079 and IEC 61340-5-1, among others. Please also observe application-specific and national standards that may deviate from these international standards.

How is the electrical conductivity in the system tested?

The electrical conductivity of the PA-EX clamps depends on the overall system. After installation, an earthing check must be carried out by suitably qualified personnel to ensure compliance with the leakage resistances.

What is the difference between primary, secondary, and tertiary explosion protection – and how do PA-EX clamps from STAUFF contribute to safety in EX zones?

Explosion protection is divided into three levels: primary, secondary, and tertiary.

Primary explosion protection aims to prevent the formation of an explosive atmosphere in the first place. This is achieved by avoiding combustible substances or limiting their concentration.

Secondary explosion protection comes into play when a hazardous mixture has already formed. The goal is to eliminate potential ignition sources, for example through smoking bans, temperature monitoring, grounding, or the use of electrically conductive materials (such as the STAUFF PA-EX Clamps) to prevent electrostatic charging.

Tertiary explosion protection (also known as constructive explosion protection) mitigates the effects of an explosion, for instance through pressure-resistant enclosures, explosion venting devices, or flame arresters.

Newsletter registration

Subscribe to the newsletter now and never miss a new post on the STAUFF blog again