STAUFF Clamps Comparison: When to Choose Each?

When multiple pipes, tubes, hoses, or cables in a hydraulic system need to be securely fastened, the question often arises: Should you use Standard DIN Clamps or Multi-Line Clamps? Both options have their own advantages, which should be considered according to your project's specific requirements. In this post, we explain when each type of clamp is best suited for your application.

Versatile Applications of Standard DIN Clamps

STAUFF Standard DIN Clamps according to DIN 3015 are a reliable and flexible solution for various mounting needs. They are suitable for pipes and tubes with diameters from 6 mm to 450 mm, offering broad coverage for different application scenarios.

These clamps provide high flexibility as they allow pipes and tubes to be easily replaced or new pipes / tubes to be added without altering the entire system. They are especially useful when compatibility with components from other manufacturers is important. Due to their universal design, Standard DIN Clamps can be easily integrated into existing systems.

An additional important advantage is the metal cage. It provides structural stability in case of fire: the plastic clamp body may burn, but the bottom weld plate, top cover plate, and side bolts keep the pipe or tube in position. This prevents it from falling from the machine and keeps it sufficiently secure even in extreme situations.

When Are STAUFF Multi-Line Clamps the Right Choice?

If multiple lines need to be laid in parallel, STAUFF Multi-Line Clamps offer significant advantages. They are more compact and require up to 30 % less installation space compared to Standard DIN Clamps, which is especially beneficial in systems with limited space.

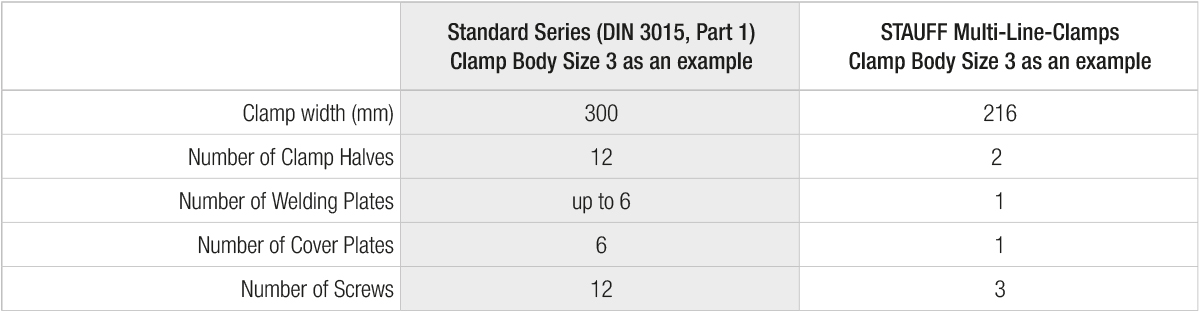

Multi-Line Clamps also significantly reduce the number of components, which shortens installation time and lowers costs. Compared to Standard DIN Clamps, which might require 12 bolts to secure six pipes or tubes, a Multi-Line Clamp only needs three bolts for the same number of lines. This also reduces the total weight of the system, which is advantageous in many applications.

This space-saving design and reduced number of components make Multi-Line Clamps especially suitable for applications that prioritize lightweight construction and where weight is a crucial factor.

However, Multi-Line Clamps offer less flexibility for later modifications to the system. Adding or removing lines requires more effort compared to the flexible Standard DIN Clamps.

Comparison of Key Criteria

The diagram below provides a visual and summarized overview of the pros and cons of different clamps. The figures refer to an example of 6 lines being attached. It’s essential to remember that there is rarely only one choice. Depending on the project and application, different products may offer distinct advantages.

The respective fire protection and safety concepts should also be taken into account: Standard DIN Clamps offer an additional safety level due to their metal cage structure, which keeps the piping network stable in case of fire. Multi-Line Clamps, on the other hand, are advantageous in space- and weight-constrained systems due to their lightweight design and space-saving benefits.

The key is to know what you want to focus on and what you value the most.

Which Clamp Suits Your Project?

The choice between Standard DIN Clamps and Multi-Line Clamps depends on several factors that should be aligned with your specific needs and conditions:

If space and weight are essential factors, Multi-Line Clamps are the optimal solution. They save installation space and weight and are particularly suitable for applications with multiple parallel lines.

However, if high flexibility and compatibility with other components are needed, Standard DIN Clamps are the better choice. They also offer advantages in reducing electrostatics and allow for easy system maintenance and expansion.

FAQs

When should STAUFF Multi-Line Clamps be used instead of Standard DIN Clamps?

How do the two clamps differ in terms of flexibility?

Standard DIN Clamps offer more flexibility in installation and maintenance, allowing easy pipe or tube replacement and expansion. Multi-Line Clamps are less flexible as they are less suited for subsequent system changes.

What materials are available for STAUFF Clamps?

Both types of clamps are available in various materials, including polypropylene (PP), polyamide (PA), and flame-retardant polyamide (PA-VO). For specific requirements, such as fire protection in marine or rail applications, additional materials like PP-VO and PP6853 are available.

Standard DIN Clamps are also available in aluminum, making them suitable for particularly demanding areas, such as those with high loads or temperatures up to 300 °C.

Can Multi-Line Clamps be used for lines with different diameters?

Yes, STAUFF offers Multi-Line Clamps that can accommodate lines with different diameters upon request. This allows for flexible adjustment to individual system requirements.

How does the choice of clamp affect system weight?

Multi-Line Clamps offer significant weight savings as they require fewer components and have a more compact design. This is particularly beneficial in systems with strict weight restrictions.

Newsletter Subscription

Never miss a new post from the STAUFF Blog